So I'll get on with something else. Early on we looked at the muffler. Here is that picture again to remind us of what we are trying to achieve.

I thought this might be difficult but really all I have to do is saw a piece of aluminium tube at the right angle, and I have no trouble with that. Any mess just gets filed away. Before I saw it I ream out the end of the smaller part with my knife as it will be harder to do once I cut the part free.The other section is long enough that I won't have any handling problem.

There's the first attempt. I got pretty close but the angle wasn't quite right. It's joined with superglue.

So I have another go. And another. This one is a keeper. Sixth attempt.

I have to say, I consider this an improvement.

I'll keep this plastic part, the exhaust pipe itself. I need to do a few things though. I need to drill out the business end - easy-peasy. But where the exhaust pipe goes into the flame damper (that's what that big elbowy thing is - it was to hide any sparks or flames at nighttime) we have what looks like a nightmare. That disc on the exhaust pipe has to come off and so does the little collar.

I don't know if you have Milo where you are - chocky drink. It comes with this steel foil seal, very useful stuff. I got this one out with the minimum of crumpling. I will try to make those fins inside with this material. The little hose-clamp part doesn't bother me, that will be fairly easy, but those fins/braces look hard.

Speaking of drilling, these are pin-vices. I have quite the collection as you can see but I use this aluminium one by Proedge pretty much exclusively because it is so light, meaning it is less likely to break the finer drill bits.

I want this yet thinner but we are in the danger zone; The plastic is starting to whiten under the stress and if I push it the rim will break. Still I have options. I can move the drill about a bit, angle it. And I can put the point of my knife in there and twiddle it ever so gently with the only force being the weight of the knife itself. With a blunt blade, not a sharp one.

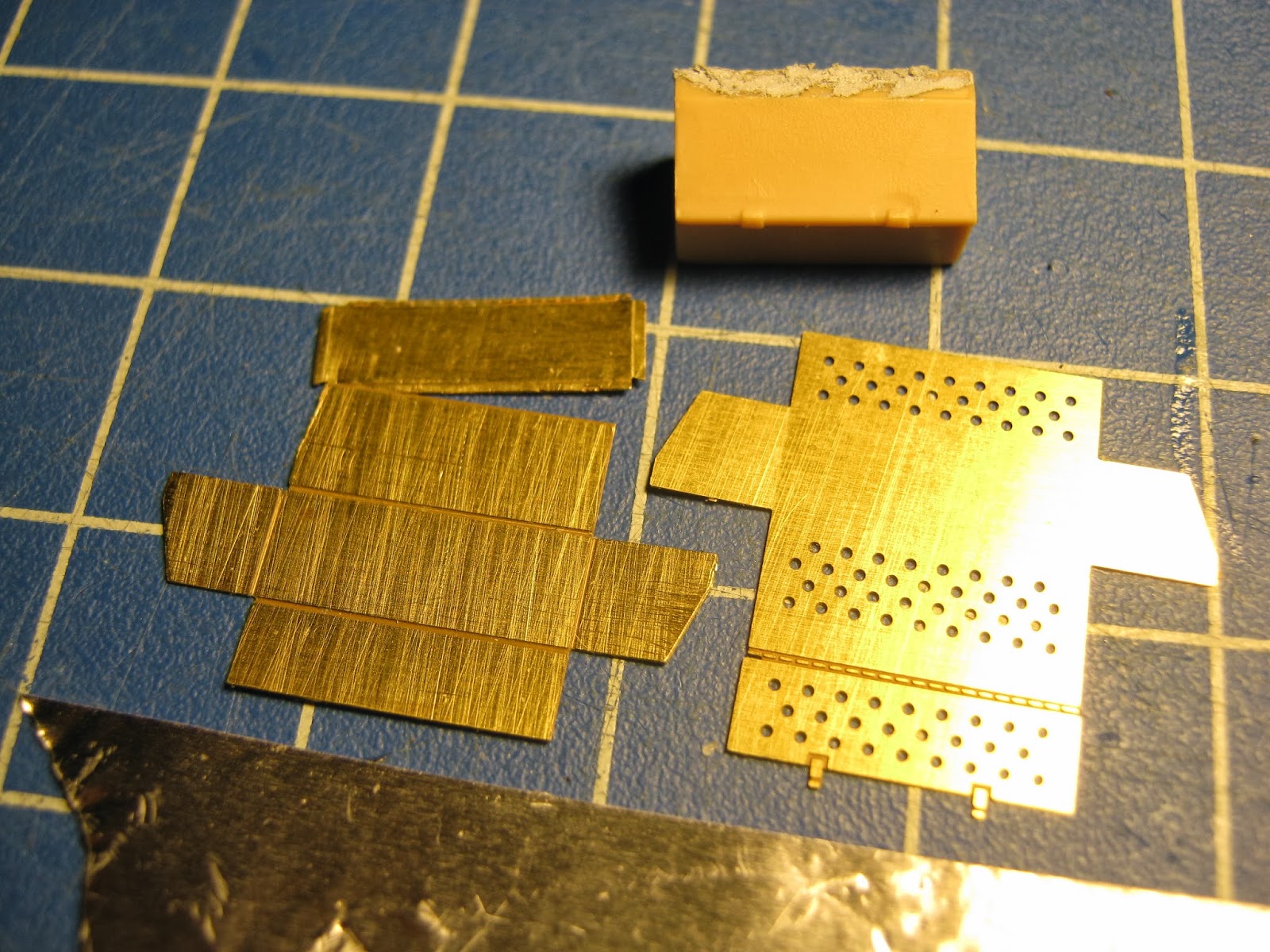

Okay, we have been trying all sorts of things. As you can see, I tried to bend up the braces with the thin sheet steel. I am not doing too well, as you can see. But then, a stroke of genius! I decide that before I can put these details on I really need to put the plastic exhaust pipe and the metal cover together. There on the right, that's a cigarette filter, and it sleeves snugly inside the elbow joint. All I have to do is cut off a bit of it, poke the exhaust pipe through the middle, and slide the whole thing inside the damper. Then, when I've got everything perfectly lined up, I can inject diluted Aquadhere into the filter and it should set fairly firm. Now the whole thing will be stable enough for me to apply the last remaining details. Do I dare to put that dent in it? Knowing I could so easily break it? I guess I can do a trial with one of the earlier attempts.

This is what I mean. I will fill those ejector pin marks, don't want anyone looking up my muffler and finding something wrong.

This cigarette filter was such a good idea. And on that high note let me bid you good night XD