The wooden block that goes with the jack is, happily for me, an ugly affair.

I find a bit of beech - can't locate the maple. I sand it to size and chisel little rebates for the metal straps. I don't do a very precise job but in this case that is okay because the thing I am trying to model is not precise either. I've got the grain of the wood the wrong way but there's no turning back now. Anyway, you've seen the brass etched part; it was hopeless and the kit part was a joke (sorry Academy, you dropped the ball on that one). This jack block is better than either of them so I'm going to sign off on it.I guess that's the difference between modelling armour and modelling planes; with armour you can make a bit of mess, fudge things here and there, hide your mistakes under accessories or mud. With planes you can't do that; everything has to be spot on. I haven't made a plane since I was a child; maybe I should.

I'm getting dangerously close to painting time. I have only to add some brackets, which I will cunningly leave open (I can't put the tools in them and hope to paint them well in situ) such that I can put the painted tools in and close them when I've got the vehicle base coat on.

I have to put on many, many hooks, the smallest hooks I have ever attempted. Because they are so delicate I'll do those last of all otherwise I'll probably keep breaking them off while I am working. There are a few other little bits and pieces. I can use these and get an acceptable result but really what I need to do is build a jig and bend them out of copper rod. We shall see.

This is what they really look like. I have to get them in the right places, straight, and in line, and I don't fancy my chances.

Let's make the brackets for the jack. In fact, let's make all the remaining tool brackets and get them out of the way.

Here is the photo.

Here are the kit parts. I've looked through my book and I see no

evidence at all for a folding handle. If there were, this handle would

be too long and too thin. I'm going to shear it away but keep the pin.

To make the new handle I'll mount a bit of aluminium tubing on my Dremel

and try to put a tiny bit of a barrel effect on it. I'll be able to

stick a pin in the end.

For the brackets, here are the brass parts and their instructions. Scary. That H thing is the kit part.

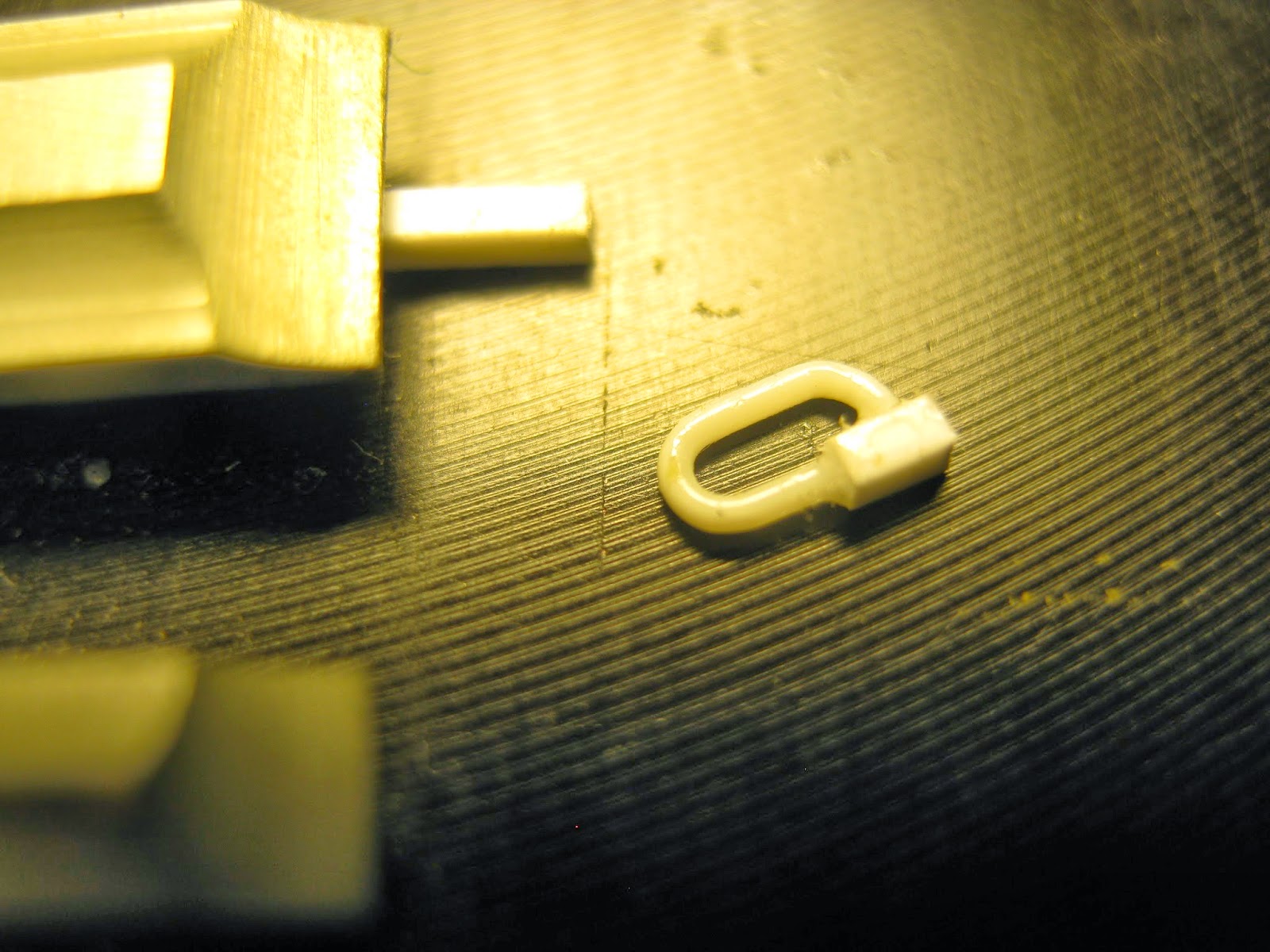

Noice. I'm getting better at this folding business.

Now let's see about that not-fold-away handle -_-

Chop!

Comes away easily with just two cuts - good old chisel blade.

Clean it up and make a handle from stretched sprue, which I drill so I can mount it easily and cleanly.

Now stretch some more sprue, this time fairly fine.

This is how you make bolts - by holding the end of the sprue up to the candle. Or at least it's how you make A bolt because good luck to you getting two the same. Luckily I only need one of these things -

- to put on the end of the handle. But the handle seems to me now to be a tad long. So I cut it off where it meets the crank and remount it -

- on the wrong side of the crank. Bugger it.

All better. I won't mount the handle just yet, I want the jack in the brackets first so I can rest the handle against the hull as per the photograph.

And then I enter into a nightmare realm, and there I dwell for many hours. I tried to fit the jack mounts, and the latch for the sledgehammer. The brass instructions are approximate in their indication of exactly where to place these things. There is some variation in the photos I have. I could not make the jack mounts relate to the sledgehammer mounts, and nor could I see where the stay for the skirt was supposed to fit in. I made a distressing superglue mess. So I took the Track guard off completely. I used superglue debonder to dissolve and remove all the errant superglue. I stood the jack mounts in two more little ponds of the stuff and they are still there; hopefully in a moment when I pick them up I will be able to wipe the glue off their feet. Then, I put the track guard back on and fit just that one skirt, whose stay/strut I will need to work around. This will become my reference point because at least I can be fairly sure where it goes. Now I think I have a clearer idea of where to place the other bits. The two little holes in the hull are for the kit crowbar fixtures. This is clearly incompatible with the shovel mount (as provided). In many of the photos I have, there is no shovel and no shovel mount. I will remove the shovel mount. I'll tuck the shovel in somewhere, as I please.

I put the crowbar mounts in place. I see that bit of glue under the top bracket - don't worry, it's gone.

I can't bear to leave things in a state and now I'm back on square one and feeling a little better. And so to bed.

See, no hook. I don't get it. The hatch next to it has a hook. How was it opened from the outside - pocketknife? Big magnet?

See, no hook. I don't get it. The hatch next to it has a hook. How was it opened from the outside - pocketknife? Big magnet? Pretty certain by now that the styrene glue I'm using either is not working, or I have two or more radically different types of styrene. I use Araldite for this one. When it's dry I'll file it clean up the excess glue very carefully as I suspect styrene is one of the few things that epoxy does not bond so well with.

Pretty certain by now that the styrene glue I'm using either is not working, or I have two or more radically different types of styrene. I use Araldite for this one. When it's dry I'll file it clean up the excess glue very carefully as I suspect styrene is one of the few things that epoxy does not bond so well with.